Merlin MRP Software

Materials Procurement for Manufacturers and Assemblers

Easy to learn, this MRP software has a built-in User Guide, with detailed help on every screen, and our Getting Started guide on the Overview page on this site.

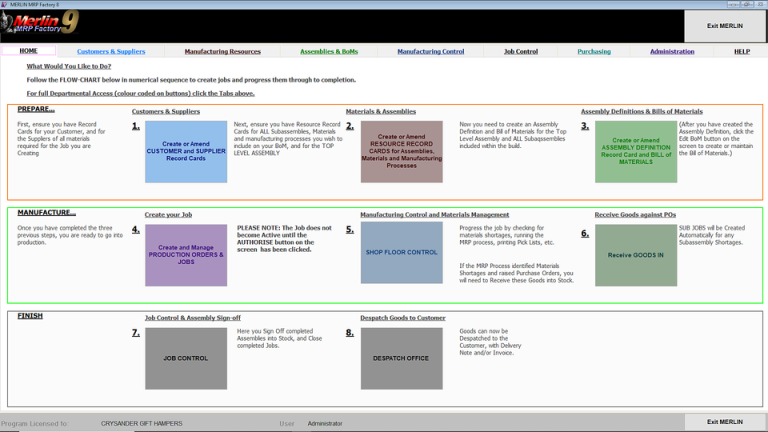

Just follow the Work-Flow on the Merlin Home Screen ,and you will quickly find how easy to use is the very powerful Merlin MRP Factory 9

You don’t have to take our word for how good this MRP System is, just download Merlin MRP Factory 9, and start using it free of charge.

Yes, you can start working with our MRP system instantly, without paying a penny up front!

Easy to learn, this MRP software has a built-in User Guide, with help on every screen.

Just follow the Work-Flow on the Home Screen (see the SOFTWARE page), and you will quickly find how easy to use is the very powerful

Merlin MRP System.

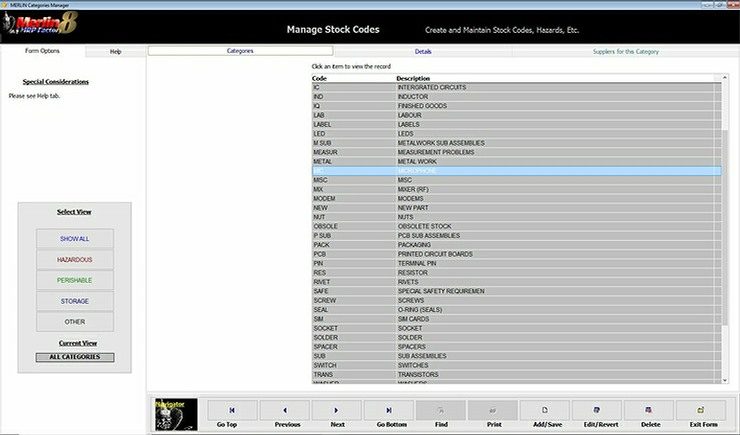

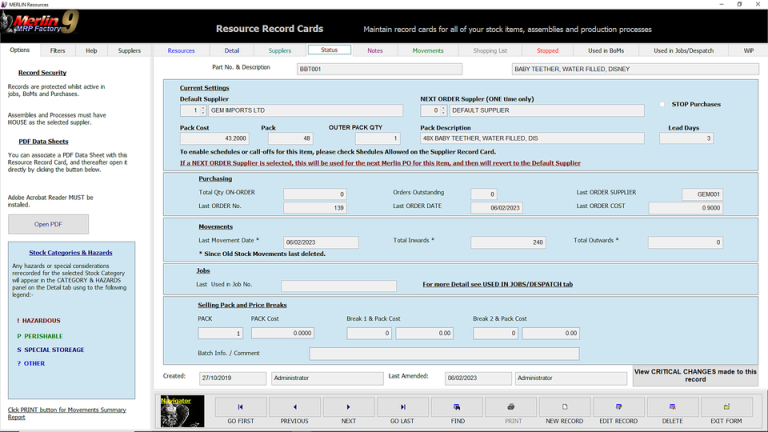

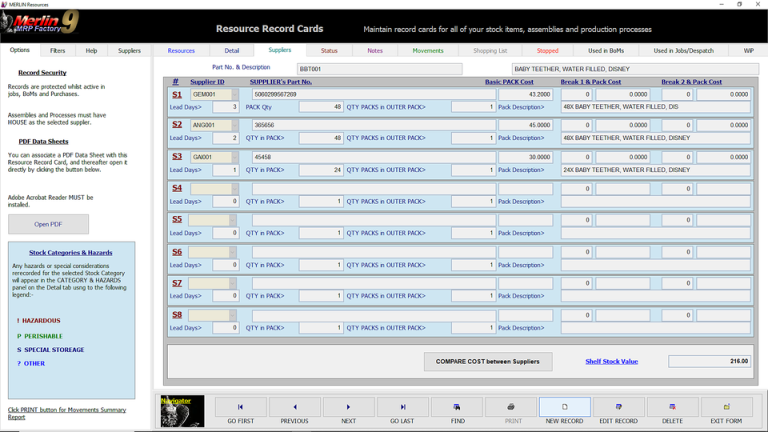

Using a combination of Stock Control and the MRP process, you can determine precisely which items you want to hold in stock, with Minimum Stock Level options, and which items you wish to procure on a JiT basis, by single job or groups.

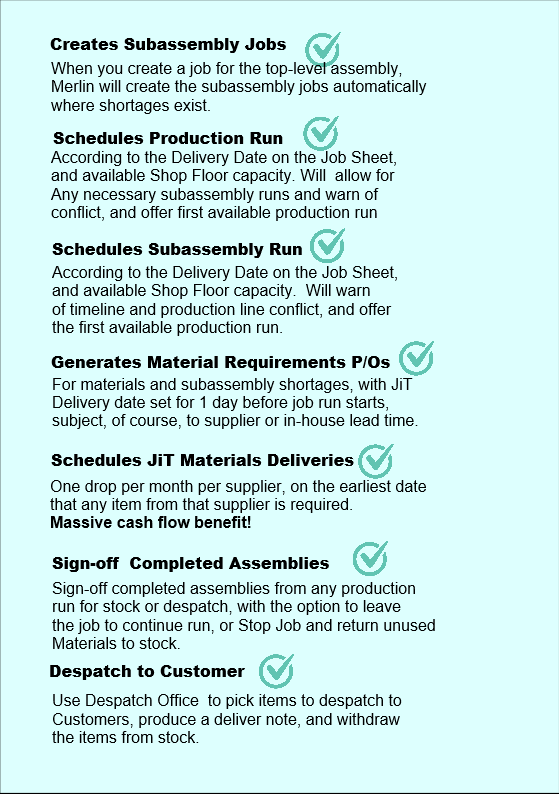

The system will analyse your production jobs for shortages, will generate work orders for subassemblies, and it will auto-create and schedule the subassembly Jobs. It will then drill-down for shortages of materials according to the BoM (Bill of Materials), create Purchase Orders, and Delivery Schedules according to the start dates of the jobs.

It will enable you to track production through the shop floor processes, and alert you to jobs running late, or in danger of running late, and warn you of shop floor conflicts when creating new production jobs. You can sign-off to stock completed assemblies as they become available, and despatch them to your customer using Despatch Office.

You can download and try our MRP software system free of charge, and will be able to enter up to 50 Resource Record Cards (think of them as Stock Record Cards for now), you can learn to use the software easily and quickly, with help tabs containing the User Guide on every screen, and our free 24/7 Help Desk when you need a bit more.

You can even run real production jobs straight away, until you are satisfied that the software is just what you need.

Start small and grow. If your business in new, or you wish to phase-in and MRP system in an existing plant, you can start with a single desk, and roll-out seats across your network as and when you are ready.

If you already have data in electronic formats (spreadsheet, CSV, etc.) we can import it into

Merlin MRP Factory 9 to get you off to a flying start!

No salesman will bother you, we promise, and when you are ready you can buy your licence(s) for your single concurrent user, or multi-seat network MRP system.

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details and accept the service to view the translations.